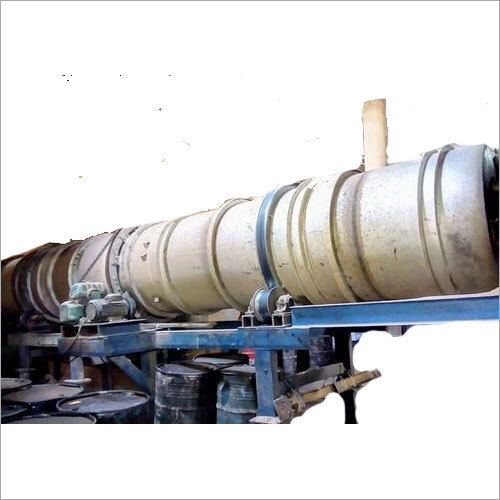

Drum Dryer

Price 700000 INR/ Unit

Drum Dryer Specification

- Usage

- Industrial

- Material

- Aluminum

- Size

- Different Available

- Product Type

- Drum Dryer

- Color

- Silver

- Warranty

- Yes

Drum Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7 Minutes

- Main Domestic Market

- All India

About Drum Dryer

We are engrossed in supplying the top-of-the-line Drum Dryer that is used to obtain a porous and easy-to-rehydrate dried product. The dryer is used widely in industrial applications. It has got high build quality, unmatched resilience, and ruggedized construction. The offered dryer has got the capability of enduring impacts, heavy loads, and tough conditions. It does not degrade in quality or become inferior in the long run. Drum Dryer is easy to install and operate. Our customers can get the dryer at a reasonable price from us.

Specification

| Service | OEM |

| Material | MS (moc) |

| Size | 1.8 m dia by 12 m length |

| Brand | PM |

| Color | Grey and orange/ as per demand |

| Rotation Speed | 1-30 RPM |

| Heating Source | Steam,Coal,Oil,Natural Gas |

| Feed Rate Range (Ton) | 1-20 TPH |

| Customisation | Customised |

| Drying Medium | air |

| Moisture Sensor | Yes |

| OEM Service | Yes |

| Condition | New |

| Power Source | gas/ diesel/ steam/ electric/ |

| Diameter (Cm) | upto 300 |

| Automatic Grade | Automatic |

| Max Temperature | 700 digree C |

| Capacity | 1-40 Ton per hour |

Durable Construction with Versatile Sizing

Crafted from premium aluminum, our Drum Dryer ensures lasting durability while promoting rapid heat transfer for efficient drying. With various sizes available, this unit accommodates an array of industrial processing capacities and requirements. Its silver finish not only looks modern but also enhances corrosion resistance in demanding environments.

Comprehensive Industrial Application

Designed for a broad range of industrial uses, this Drum Dryer streamlines the drying process for chemicals, food products, pharmaceuticals, and more. Its robust build and adaptable sizing make it the preferred choice across different manufacturing sectors. Backed by our extensive support as an exporter, importer, and manufacturer, youll receive expert guidance, installation, and service.

FAQs of Drum Dryer:

Q: How does the drum dryer work in an industrial setting?

A: The drum dryer operates by rotating a heated drum onto which the material is applied in a thin layer. Moisture evaporates as the drum turns, resulting in efficient and uniform drying, making it suitable for high-volume industrial processes.Q: What types of materials can be processed with this drum dryer?

A: This drum dryer is engineered for diverse industrial applications, including drying powders, chemicals, food products, slurries, and pharmaceuticals. Its adaptability makes it a versatile solution in various sectors.Q: When is the optimal time to use a drum dryer in production?

A: The drum dryer is best employed during stages where rapid and uniform moisture removal is essential before subsequent processing or packaging. It excels in continuous production lines requiring consistent output quality.Q: Where can the drum dryer be installed within an industrial facility?

A: The drum dryer is typically installed in centralized processing zones, near material feeding lines or post-processing areas where moisture evacuation is critical. Its multiple size options allow integration into facilities with varying spatial constraints.Q: What is the process for ordering and receiving installation support?

A: Simply contact us as your exporter, importer, or service provider. After confirming size and specifications, we arrange delivery, offer guidance for installation, and provide comprehensive after-sales support including warranty coverage.Q: How do users benefit from using an aluminum drum dryer with a warranty?

A: Aluminum construction ensures superior corrosion resistance and efficient heat transfer, leading to faster drying cycles. The included warranty gives assurance of reliability and dedicated support throughout the products operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dryers Category

Tray Dryers

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Tray Dryers

Warranty : Yes

Usage : Industrial

Color : Silver

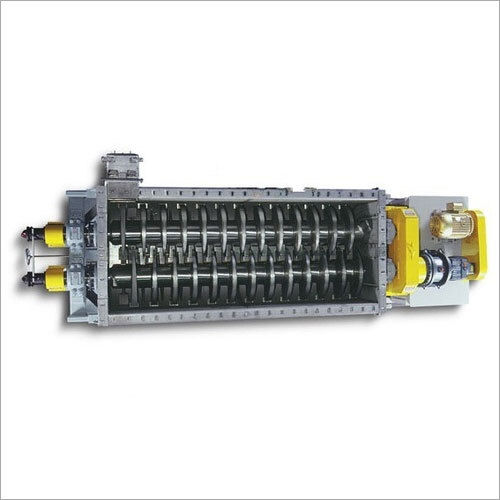

Paddle Dryer

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Paddle Dryer

Warranty : Yes

Usage : Industrial

Color : Silver

Vacuum Dryer

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Vacuum Dryer

Warranty : Yes

Usage : Industrial

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry